Preface

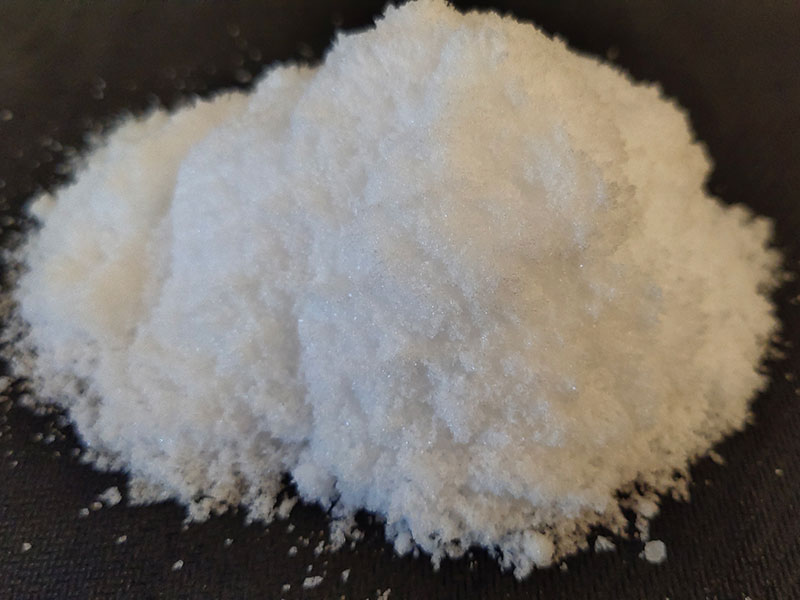

In the production of waterborne polyurethane, carboxylic acid as anionic hydrophilic chain extender is a kind of carboxylic acid with diol, which has been widely used for its unique molecular structure and excellent product performance.

Carboxylic acid type chain extender mainly includes 2,2-dihydroxymethylpropionic acid (DMPA) and 2,2-dihydroxymethylbutyric acid (DMBA). It is a unique multifunctional blocked diol molecule with both hydroxyl and carboxyl groups. After neutralization with alkali, the free acid group can actively improve the water solubility or dispersion performance of the resin; Polar groups were introduced to improve the adhesion of coatings and the dyeing properties of synthetic fibers; Increase the alkali solubility of the coating. It can be applied to water-soluble polyurethane system, water-soluble alkyd resin and polyester resin, epoxy ester coating, polyurethane elastomer and powder coating.

It can also be used in leather chemical materials, liquid crystals, inks, food additives and adhesive chemicals, especially in the manufacture of water emulsion polyurethane and leather finishing agents. It is not only a chain extender, but also a good self emulsifying agent for polyurethane, which can greatly improve the stability of polyurethane water lotion, so it is widely used.

Advantages Of Using Dihydroxymethyl Carboxylic Acid

Aqueous polyurethane lotion usually introduces hydrophilic agent into polyurethane molecular chain, then neutralizes with alkali to form salt, and disperses in deionized water by mechanical stirring to form polyurethane aqueous lotion.

There are mainly three types of hydrophilic agents used in waterborne polyurethane: anionic, cationic and non-ionic. The anionic type mainly includes: 2,2-dihydroxymethylpropionic acid, 2,2-dihydroxymethylbutyric acid, tartaric acid, butanediol sulfonate, sodium ethylenediamineethanesulfonate, glycerol and maleic anhydride; Cationic type mainly includes: methyldiethanolamine, triethanolamine, etc; Non ionic type mainly includes hydroxyl terminated polyethylene oxide.

The content of non-ionic hydrophilic agent such as polyethylene oxide must be very high to make the dispersion stable. The waterborne polyurethane resin made of hydroxyl polyoxyethylene ether as hydrophilic group has good electrolyte resistance, but the water resistance of the film is very poor, so it is not practical;

Cationic hydrophilic agent, such as ethylenediamine sodium acrylate adduct, as a hydrophilic compound, makes the whole reaction system alkaline. There is not only a rapid reaction between - NH2 group and - NCO group, but also a reaction between - NCO group and - nhcoo. Therefore, the reaction is difficult to control and is easy to gel. Moreover, the prepared lotion has coarse particles and poor film-forming water resistance, so it can not be used in industry;

The Dihydroxymethyl carboxylic acid in the anionic form contains two hydroxyl groups and also acts as a chain extender. This dual role makes it show great advantages in the preparation of self emulsifying Pu lotion. During the synthesis of carbamate, it makes the reaction system acidic. Under acidic conditions, the reaction between - NCO and - Oh is mild, while - nhcoo - does not participate in the reaction and will not cause gel. In addition, dimethylol carboxylic acid also acts as a chain extender, so that the hydrophilic group (i.e., carboxyl group) is located in the macromolecular chain segment. Using tertiary amine as a neutralizing agent, an aqueous polyurethane resin with excellent stability and excellent film-forming water and solvent resistance can be prepared. Dihydroxymethyl carboxylic acid is the best hydrophilic compound widely used in the preparation of waterborne polyurethane resin.

2,2-Dihydroxymethylpropionic Acid (DMPA) And 2,2-Dihydroxymethylbutyric Acid (DMBA)

Among the two kinds of Dihydroxymethyl carboxylic acids, 2,2-dihydroxymethyl propionic acid has been used for a long time and is a hydrophilic chain extender widely used at present. Although it has many advantages, it also has many disadvantages, mainly due to its high melting point (180-185 ℃), which is difficult to heat and melt, which requires the addition of organic solvents such as N-methylpyrrolidone (NMP), n N-dimethylamide (DMF), acetone, etc., while NMP has a high boiling point, which is difficult to remove after preparing APU. Moreover, DMPA has a small solubility in acetone, and a large amount of acetone needs to be added in the synthesis process. The ketone removal process not only wastes energy but also brings safety risks. Therefore, the use of 2,2-dihydroxymethylpropionic acid is not only high in energy consumption, but also easy to cause organic residues in the product.

Compared with 2,2-dihydroxymethyl propionic acid, 2,2-dihydroxymethyl butyric acid has the following advantages:

1. It has better solubility in organic solvents. The following table shows the solubility data of DMBA and DMPA in different temperatures and solvents;

Solubility data of DMBA and DMPA in different temperatures and solvents:

|

Serial number |

Temperature℃ |

Acetone |

Methyl ethyl ketone |

Methyl isobutyl ketone |

|||

|

DMBA |

DMPA |

DMBA |

DMPA |

DMBA |

DMPA |

||

|

1 |

20 |

15 |

1 |

7 |

0.4 |

2 |

0.1 |

|

2 |

40 |

44 |

2 |

14 |

0.8 |

7 |

0.5 |

Solubility: unit: g / 100g solvent

Solubility in water: 48% for DMBA and 12% for DMPA.

2. High reaction rate, fast reaction speed and low reaction temperature. For example, the reaction time for synthesizing polyurethane prepolymer is short, generally only 50-60 minutes, while DMPA takes 150-180 minutes;

3. It is used for waterborne polyurethane lotion with finer particle size and narrow distribution;

4. Low melting point, 108-114 ℃;

5. The diversity of formulas can reduce the use of solvents, thus reducing the cost of solvents and waste liquid treatment;

6. It can be used to prepare completely solvent-free polyurethane and polyester systems;

In the actual synthesis process, it does not need to consume any solvent. The lotion produced has good performance and excellent mechanical properties of the film, which not only shortens the reaction time, reduces energy consumption, but also saves energy. Therefore, 2,2-dihydroxymethyl butyric acid is the best known hydrophilic compound.

Post time: Sep-13-2022