Application

Polyurethane Synthetic Leather For Shoes

Microfiber Synthetic Leather

Polyurethane synthetic leather based on three-dimensional network structure microfiber nonwovens is a new generation of synthetic leather developed this year. Due to the huge specific surface area and strong water absorption function of the microfiber, the microfiber synthetic leather has the moisture absorption characteristics, so it can be comparable to the natural leather in terms of internal structure, appearance texture, physical characteristics and wearing comfort. Many high-end shoes use super fiber leather, which is no less than real leather in terms of hand feel, aesthetic feeling and breathability. It has been proved that synthetic leather has largely replaced the natural leather with insufficient resources with its excellent properties, which satisfies the application of footwear industry.

Requirements For Shoe Leather

In modern life, polyurethane synthetic leather (PU) is more and more widely used in high-quality men's and women's shoes, children's shoes and sports and leisure shoes. The innovation of shoe technology and technology puts forward more and more higher requirements for PU leather.

(1) PU leather for fashionable casual shoes and leather boots emphasizes hand feeling and visual sense: it requires strong leather sense, fullness, softness, good tactility, excellent resilience, small wrinkling, diversified patterns and colors, novel fashion and unique style;

(2) Professional sports functional shoes and boots usually require light, thin and comfortable materials; The finished product is light, flexible and strong, which can not only ensure the excellent function of the product, but also meet the requirements of comfortable wearing, such as excellent waterproof, breathable and moisture absorption characteristics;

(3) Protective shoes and boots require that the shoe materials have excellent physical properties and comprehensive properties: high peel strength, tear strength, tensile strength, bursting strength and suture strength, which can provide excellent protective effect for shoes and boots, stable color, durable and durable, and can have excellent wear resistance, scratch resistance, yellowing resistance, aging resistance, cold resistance, solvent resistance and hydrolysis resistance, and can meet the requirements of wearing in humid, hot, extreme and harsh environments;

(4) Shoes and boots or unsealed professional shoes and boots worn under specific working environment usually require special functionality and versatility: for example, they have single or multiple functions such as easy decontamination, flame retardancy, insulation, water and oil resistance, antibacterial and mildew resistance, which are conducive to human health, safety, hygiene and comfort, and improve the living and health level of consumers;

(5) Requirements for material processing performance in large-scale production of shoes: easy to cut, stable in size, not easy to deform, good qualitative effect of processing and molding, and fully meet the requirements of footwear processing; The finished product is not easily deformed and meets the requirements of leisure, sports and other activities;

(6) In addition, shoe materials with excellent environmental protection performance are expected to be used more; Ecological functional new materials with low-carbon, environmental protection functions and fashion concepts need to be further developed.

In order to meet the above requirements, PU leather technology needs to be continuously improved and improved in preparation process, coating function, raw material selection, etc., to create high-performance materials that meet various needs. The development trend of polyurethane synthetic leather for shoes is from basic to natural leather, so that it is based on the natural grain pattern of European natural leather, soft, full and elastic feel, excellent physical and mechanical properties and sanitary properties, and also more functional.

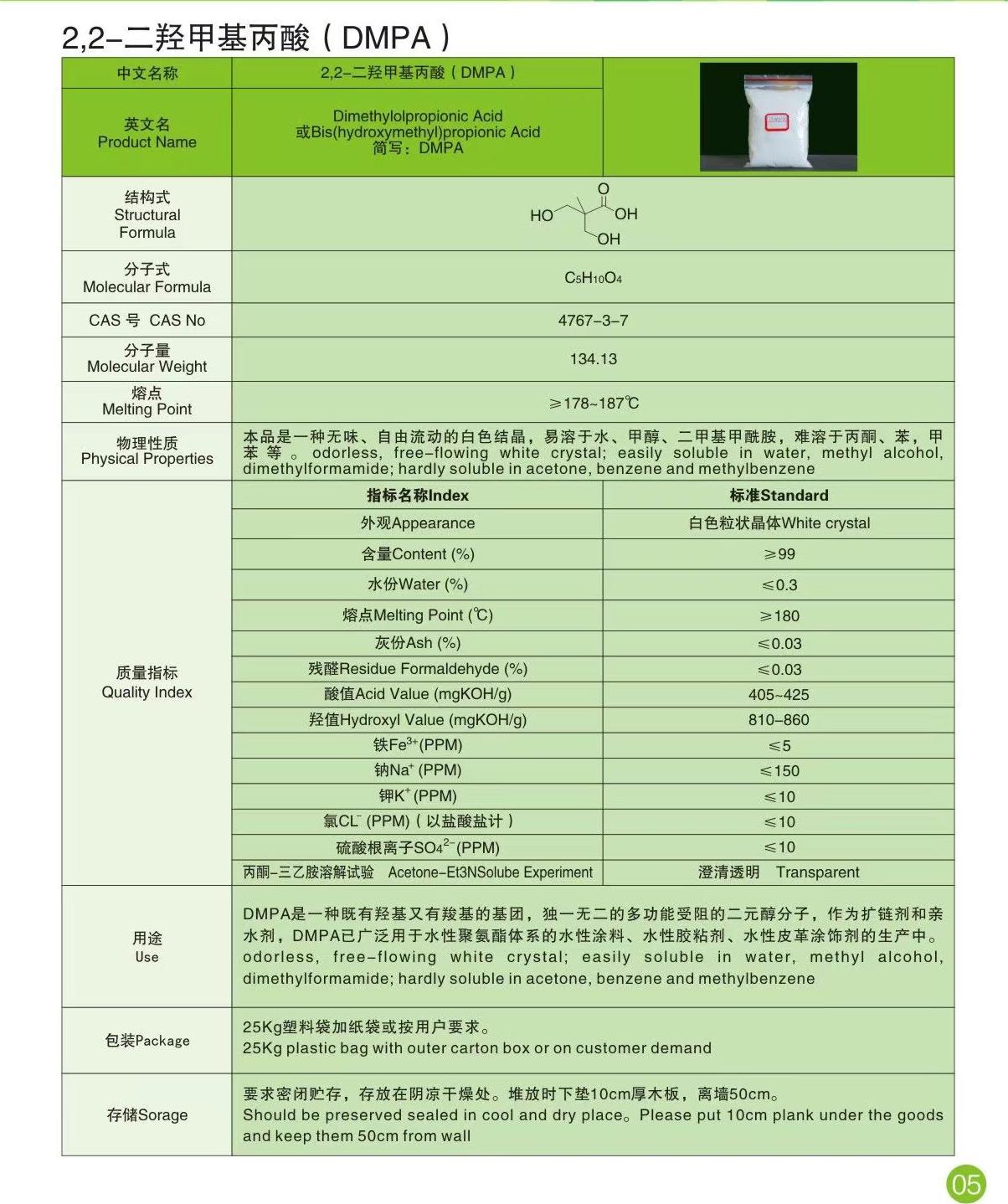

Our company is named Jiangxi Jiyu New Material Co.,ltd. It is specialized in research, manufacturing and selling of Hydrophilic Chain-Extending Agent. For example, 2,2-BIS(Hydroxymethyl) propionic Acid (DMPA) and 2,2-BIS(Hydroxymethyl) butyric acid (DMBA). DMPA and DMBA are widely used in manufacturing of water-based paint, water-based tackiness agent, water-based printing ink and water-based leather finishing agent.