-

2,2-Bis(hydroxymethyl)butyric Acid (DMBA) CAS NO. 10097-02-6 Manufacture

2,2-Bis(hydroxymethyl)butyric Acid (DMBA)

Molecular Formula: C6H12O4

CAS NO.: 10097-02-6

Molecular Weight: 149.16

Melting Point: 108~117ºC

Appearance: WHITE CRYSTAL

Purity: 99%

-

2,2-Dimethylolpropionic Acid (DMPA) for Study On Modification Of Waterborne Polyurethane Leather Finishing

In the process of leather production, finishing is a very important process, which has a very important impact on the use value of leather. With the development of economy and the continuous improvement of people’s living standards, people have higher and higher requirements for leather finishing agents, and in recent years, they have gradually moved closer to the environment-friendly type. The waterborne polyurethane leather finishing agent can effectively avoid the pollution and toxicity of traditional finishing agents, and has the characteristics of easy storage, transportation and non combustion. It has excellent performance, but it still has some shortcomings in wear resistance and water resistance. It needs relevant staff to actively explore and modify the waterborne polyurethane leather finishing agent.

-

DMBA CAS No 10097-02-6 for Study On The Application Of Water-Based Resin In Microfiber

DMBA has better solubility than DMPA. It is used as chain extender and hydrophilic agent. It is widely applied in manufacturing of water-based paint, water-based tackiness agent, and water-based leather finishing agent.

Technical problems faced by Microfiber:

1.1 lack of air permeability and moisture permeability:

After the previous treatment of super fiber leather, the surface layer and adhesive layer are treated, which leads to its air permeability and moisture permeability no longer. In general, the top resin of super fiber leather is TPU or oily PU resin, because it is easy to form a film. However, it also has some disadvantages, such as no air permeability and moisture permeability after coating. This leads to the unique performance of the super fiber being affected and no longer has advantages. -

DMPA & DMBA Widely Used For Waterborne Polyurethane Matting Resin

Our company is named Jiangxi Jiyu New Material Co.,ltd. It is specialized in research, manufacturing and selling of Hydrophilic Chain-Extending Agent. For example, 2,2-BIS(Hydroxymethyl) propionic Acid (DMPA) and 2,2-BIS(Hydroxymethyl) butyric acid (DMBA). DMPA and DMBA are widely used in manufacturing of water-based paint, water-based tackiness agent, water-based printing ink and water-based leather finishing agent.

Aqueous polyurethane is an aqueous solution, dispersion or aqueous lotion formed by polyurethane resin in water. It is widely used in building, home, automobile, leather clothing, household appliances and other decorative coatings. Waterborne polyurethane can be used to prepare matting coating. At present, the matting effect of coating resin is mainly obtained by adding matting agent and self matting modification of resin.

-

Study On Resin Modification Of Waterborne Alkyd Resin Coatings

Our company is named Jiangxi Jiyu New Material Co.,ltd. It is specialized in research, manufacturing and selling of Hydrophilic Chain-Extending Agent. For example, 2,2-BIS(Hydroxymethyl) propionic Acid (DMPA) and 2,2-BIS(Hydroxymethyl) butyric acid (DMBA). DMPA and DMBA are widely used in manufacturing of water-based paint, water-based tackiness agent, water-based printing ink and water-based leather finishing agent.

For example, our DMPA & DMBA are used for Alkyd resin coating.

Alkyd resin coating has become one of the most studied and produced coatings in the coating industry because of its easy availability of raw materials, low price and excellent gloss, flexibility and adhesion. However, the traditional alkyd resin coating has some disadvantages such as low coating hardness, water resistance and heat resistance, and its application can not meet the requirements of industrial development for high performance. It is imperative to modify and expand the application field of alkyd resin coating.

-

Study DMBA & DMPA In super Fiber Leather Application

Our products: DMPA & DMBA are widely used in manufacturing of water-based polyurethane resin, water-based paint, water-based tackiness agent, water-based printing ink, water-based super fiber leather and water-based leather finishing agent and so on.

now we firstly introduce our DMPA & DMBA use in Microfiber Leather.

1) Features of super fiber leather:

The full name of microfiber leather is “Microfiber Reinforced leather”. It has extremely excellent wear resistance, ventilation, aging resistance, softness and comfort, strong flexibility and environmental protection effect advocated now. It has been increasingly recognized by the market. Its wide range of applications, large number and varieties are beyond the satisfaction of traditional natural leather. The leather material itself has elegant color, excellent touch and bright appearance, which has an excellent advantage in the product market. Super fiber leather is generally softer than natural leather, wear-resistant, and has a better handle. It is relatively easy to take care of, with the characteristics of ventilation and warmth. And the super fiber leather is also cheaper and better than the real leather.

2) super fiber leather’s raw material is water-based polyurethane resin, yet, water-based polyurethane resin needs use our DMPA or DMBA.

-

DMBA & DMPA can be used in Water-Based Ink In PVC Color Film Intaglio Printing

DMBA & DMPA are used as chain extender and hydrophilic agent. They are widely applied in manufacturing of water-based paint.

DMBA CAS NO.: 10097-02-6

DMPA CAS NO.: 4767-03-7

DMBA & DMPA are an odorless, free-flowing white crystal. But DMPA has two kinds of appearance: FINE POWDER & COARSE POWDER.

-

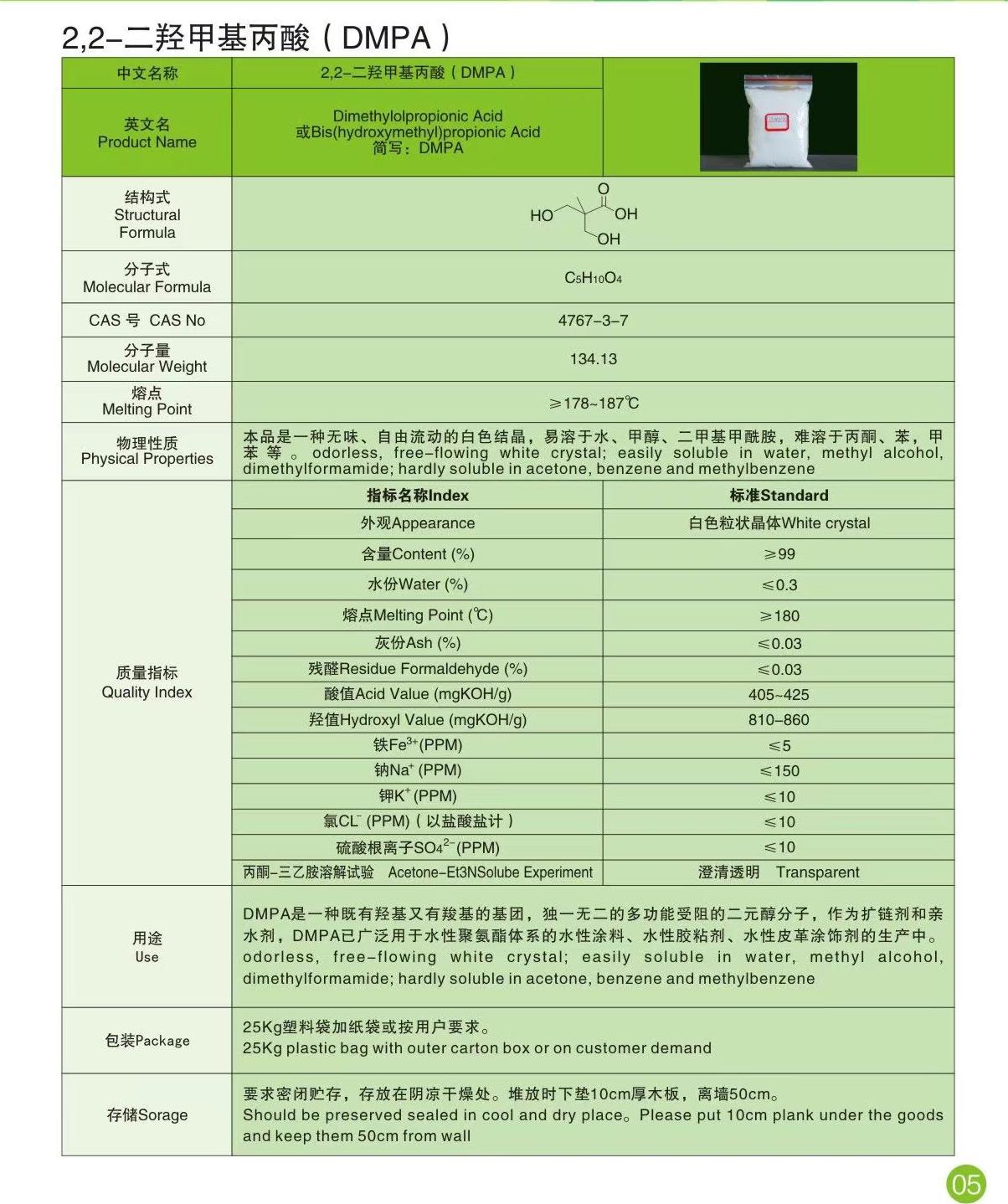

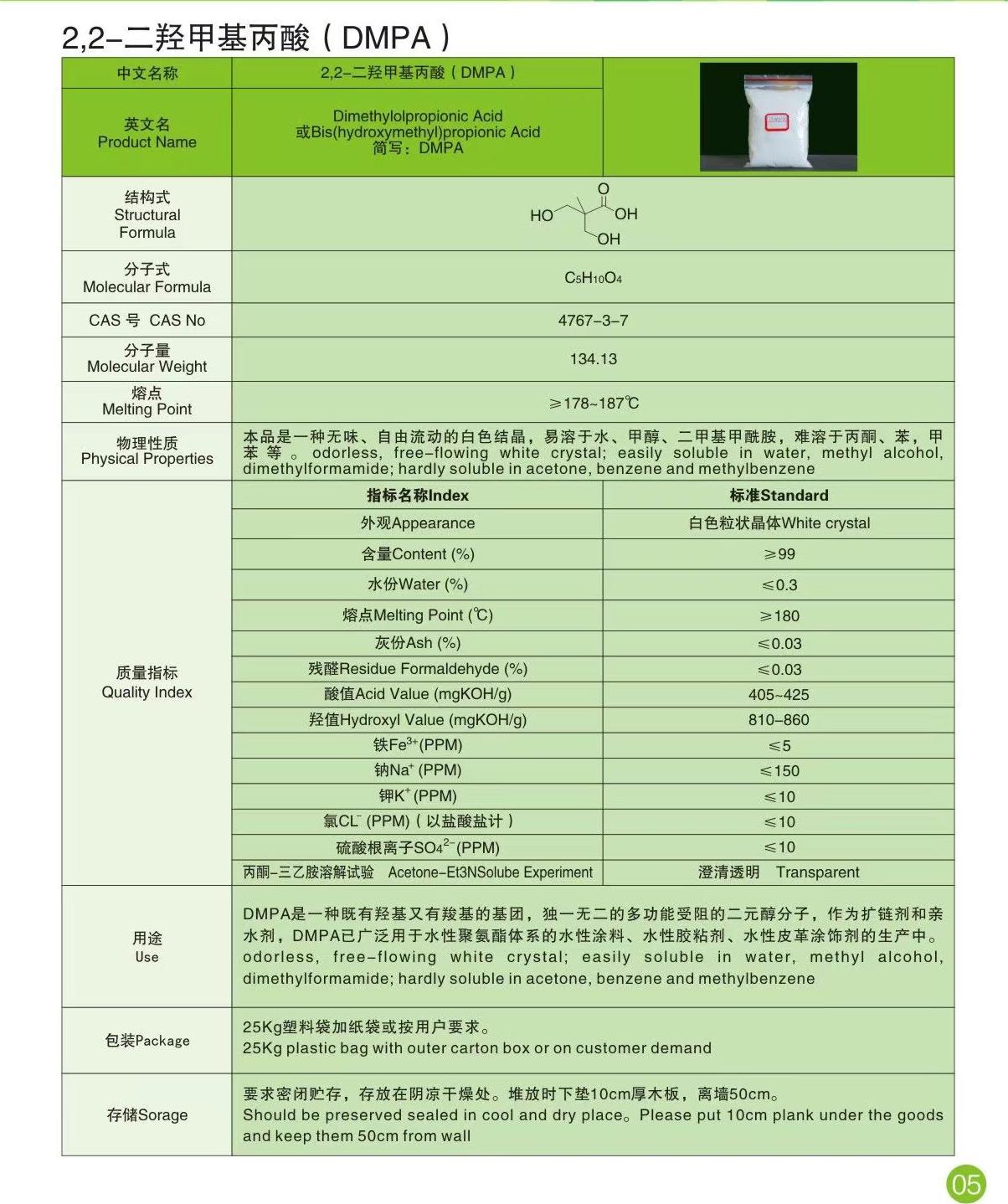

2.2-Dimethylolpropionic Acid or Bis(hydroxymethyl)propionic Acid (DMPA) CAS NO.: 4767-03-7 Manufacture

Molecular Formula: C5H10O4

CAS NO.: 4767-03-7

Molecular Weight: 134.13

Melting Point: 178~187ºC

Appearance: WHITE CRYSTAL

Purity: 99%

-

Study On The Application Of Water-Based Resin In Microfiber

Technical problems faced by Microfiber:

1.1 lack of air permeability and moisture permeability:

After the previous treatment of super fiber leather, the surface layer and adhesive layer are treated, which leads to its air permeability and moisture permeability no longer. In general, the top resin of super fiber leather is TPU or oily PU resin, because it is easy to form a film. However, it also has some disadvantages, such as no air permeability and moisture permeability after coating. This leads to the unique performance of the super fiber being affected and no longer has advantages. -

Study On Improving The Properties Of Shoe Leather

Wear resistance:

The wear resistance of vamp material is one of the important indexes reflecting the quality of shoe products. In the process of wearing, the heel often scrapes and rubs with the external environment along with the movement of people’s feet. If the upper material does not have good wear resistance, it will cause fading, fuzzing, ballooning, peeling or damage of the surface coating of the upper material, thus affecting the service life of the shoe.

-

Study On Application Characteristics Of Super Fiber Leather In Products

Features of super fiber leather:

The full name of microfiber leather is “Microfiber Reinforced leather”. It has extremely excellent wear resistance, ventilation, aging resistance, softness and comfort, strong flexibility and environmental protection effect advocated now. It has been increasingly recognized by the market. Its wide range of applications, large number and varieties are beyond the satisfaction of traditional natural leather. The leather material itself has elegant color, excellent touch and bright appearance, which has an excellent advantage in the product market. Super fiber leather is generally softer than natural leather, wear-resistant, and has a better handle. It is relatively easy to take care of, with the characteristics of ventilation and warmth. And the super fiber leather is also cheaper and better than the real leather.

-

Polyurethane Synthetic Leather For Shoes

Polyurethane Synthetic Leather:

The polyurethane synthetic leather with non-woven fabric as the base and polyurethane as the coating has a rich and soft feel close to natural leather, beautiful appearance and excellent processing performance. It has the advantages of high strength, air permeability, wear resistance, cold resistance, aging resistance, solvent resistance, tear resistance and microbial resistance. It is widely used in shoe making and gradually replaces the PVC artificial leather with relatively poor air permeability and moisture absorption and difficult to be degraded, It becomes an ideal imitation leather product instead of natural leather.