Application

Study On Resin Modification Of Waterborne Alkyd Resin Coatings

Description

At present, there are two aspects in the research on the modification of alkyd resin coatings: resin modification and pigment modification. Resin modification is to introduce other groups on the resin molecular chain segment, or with polyurethane resin, acrylic resin, epoxy resin and silicone resin. The modification of pigment and filler is mainly to add different functional pigments and fillers to improve the performance of alkyd resin coatings. This paper introduces the study on the modification of two waterborne alkyd resin coatings.

Study On Resin Modification Of Waterborne Alkyd Resin Coatings

1. Preparation of oil-water alkyd resin from Zanthoxylum bungeanum seeds by degradation of waste polyethylene terephthalate (PET) bottles

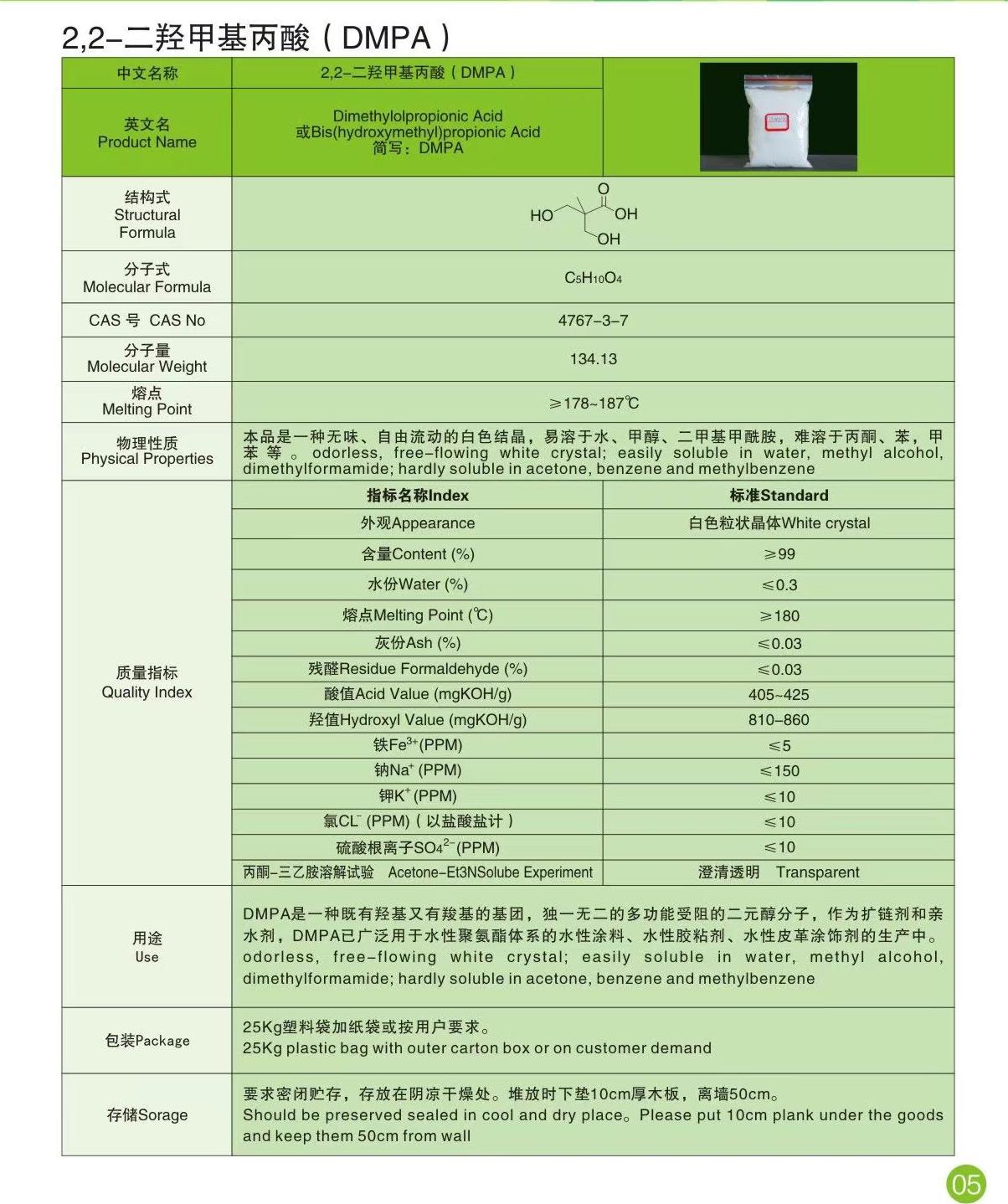

Lei Rui of Shaanxi University of science and technology, etc. prepared a pet modified oil-water alkyd resin of Zanthoxylum bungeanum seeds by using waste PET bottles, trimethylolpropane (TMP) and non edible Zanthoxylum bungeanum seed oil as main raw materials, phthalic anhydride (PA) as acidic monomer, 2,2-Dimethylolpropionic acid (DMPA) as aqueous monomer, and n, N-Dimethylethanolamine as neutralizing agent. The performance test results of the coating show that when the alcohol content is 11.5%, the oil content is 50%, w (PET) = 9.3%, w (DMPA) = 10%, the coating has good storage stability, and the water resistance, hardness and thermal stability are greatly improved compared with ordinary aqueous alkyd.

2. Silicone acrylate polyurethane modified waterborne alkyd anticorrosive coating

The alkyd resin was prepared by esterification reaction with tall oil fatty acid (TOFA), pentaerythritol and PA as main raw materials, and then the emulsifier AE 300 was added to obtain the water lotion alkyd dispersion. An aqueous polyurethane prepolymer was prepared from dehydrated diol, isophorone diisocyanate and aqueous monomer 2,2-dihydroxymethylpropionic acid (DMPA). Silicon acrylic polyurethane lotion was prepared by using TEA as neutralizing agent, adding acrylic monomer, emulsifier, silane coupling agent, initiator and chain extender. A silicone acrylic polyurethane modified waterborne alkyd coating was prepared with aqueous alkyd dispersion and silicone acrylic polyurethane lotion as main film forming materials.

Our company is named Jiangxi Jiyu New Material Co.,ltd. It is specialized in research, manufacturing and selling of Hydrophilic Chain-Extending Agent. For example, 2,2-BIS(Hydroxymethyl) propionic Acid (DMPA) and 2,2-BIS(Hydroxymethyl) butyric acid (DMBA). DMPA and DMBA are widely used in manufacturing of water-based paint, water-based tackiness agent, water-based printing ink and water-based leather finishing agent.