Application

Application Of Water-Based Environmental Protection Ink In Food Packaging

Development Prospect And Trend Of Waterborne Ink

The water-based ink is called water-based ink for short. The flexographic water-based ink is also called liquid ink. It is mainly made of water-soluble resin, organic pigment, solvent and related additives through compound grinding. Aqueous resin is a new type of resin system which uses water instead of organic solvent as dispersion medium. It is fused with water to form a solution. After the water volatilizes, a resin film material is formed. The water-based resin is not the water-based resin itself but a film material obtained after water volatilization. Waterborne polyurethane, as a representative, can be widely used in coatings, adhesives, fabric coatings and finishing agents, leather finishing agents, paper surface treatment agents and fiber surface treatment agents. Water based ink is especially suitable for food, beverage, medicine, tobacco, wine, children's toys and other packaging and printing products with strict hygiene requirements, replacing solvent based products in various fields. As one of the five elements of printing, water-based ink plays an important role in the printing process and printing quality. The reasonable allocation of ink is an important link to ensure the quality of printed products. Water based ink has been occupying a large share in flexographic printing due to its advantages of environmental protection and economy.

The strong development of the green packaging printing industry will inevitably intensify the competition in the offset printing ink market. Now the ink manufacturers have sent a signal that the cost of ink raw materials has risen sharply, which will further increase the cost of production and processing convenience. This is mainly due to the global shortage of a series of chemical agents, which are the key raw materials in the production of ink. Up to now, the rising price of crude oil and petrochemical derivatives is the main reason for the rise of ink prices. However, even if the oil price drops, because the ink industry is hit by the shortage of chemical raw materials, especially raw materials such as nitrocellulose, acrylic acid, acetic acid and titanium dioxide, the ink price will still only rise. At present, developed countries and regions are trying to develop and use ink to gradually replace solvent based ink. Packaging printing with water-based ink printing as the main development object has formed a trend in the world.

Structural Characteristics Of Water-Based Ink: The Difference Between Agent And Oil-Based Ink

The quality of polyurethane for ink mainly uses aliphatic polyester and aliphatic isocyanate as the main synthetic materials in the preparation process. Compared with aromatic polyurethane, the former has more excellent optical stability and the film after film formation has better yellowing resistance. There are polar groups such as carbamate, urethane, ester bond and ether bond in the polyurethane molecular chain segment for ink, which form hydrogen bonds with the polar groups on the surface of various polar substrates such as pet and PA, thus forming a joint with certain connection strength. After the modified polyurethane resin is made into ink, it can be printed on the surface of polar plastic substrate with good adhesion fastness. Polyurethane resin for ink is generally prepared from polyester or polyether polyol, ester ring diisocyanate and diamine chain extender. Due to the introduction of urea bond in the polyurethane resin, the polyurethane urea resin (PUU) is formed, which has good wetting and dispersing properties to the pigment.

Polyurethane resin for ink has good compatibility with aldehyde ketone resin, chloroacetic resin, etc. it can be properly added in the process formula according to the actual situation to improve the comprehensive performance of the ink. The polyurethane resin for ink is prepared by introducing urea group into the traditional polyurethane molecular segment, which greatly improves the cohesion strength and film forming property of the resin itself. Traditional polyurethane resin has a wide range of miscibility with organic solvents. However, in the process of preparing ink, in order to adjust the fluidity and viscosity of ink, it is necessary to add alcohol organic solvents, which will greatly reduce the stability of the resin system and cause turbidity, flocculent precipitation and other phenomena for traditional polyurethane resin. In the molecular chain segment of polyurethane resin for printing ink, due to the presence of urea group, the polyurethane resin and alcohol can be dissolved. However, it should be noted that the alcohol solvent is still a pseudo solvent. In the microscopic state, the alcohol solvent only encapsulates the polyurethane resin molecule, instead of penetrating the molecular polarity into the molecule like the real solvent, so that the ink prepared with polyurethane resin has good fluidity.

The main difference between water-based ink and oil-based ink is the solvent. The water-based ink uses water (45% - 50%) as the solvent, with very low VOC content and little environmental pollution; The oily ink uses organic solvents (toluene, xylene, industrial alcohol, etc.) as the solvent. The water-based ink uses water and water-soluble solvent as the main components of the dissolved color base; There are also dye ink and pigment ink in the water-based ink, and the pH is generally neutral; Oil also has dye ink and pigment ink, and pH is generally acidic. Water based ink and oil-based ink cannot be mixed in the same print head.

In water-based ink, water-based resin is an important component of water-based ink. The ink connecting material directly affects the adhesion performance, drying speed, anti fouling performance and heat resistance of the ink, and also affects the gloss and ink transfer performance. Therefore, the selection of suitable water-based resin is the key to the preparation of water-based ink. It must have good affinity with colorants, high adhesion fastness after printing and film formation, wear resistance, scratch resistance, good heat resistance, easy crosslinking and film formation. Commonly used waterborne resins include waterborne polyurethane resin, acrylic resin, polyvinyl alcohol and epoxy resin.

The waterborne polyurethane resin is dispersed in water by introducing hydrophilic groups into the polyurethane molecular chain. Waterborne polyurethane resin has the advantages of simple use, stable performance, strong adhesion, high gloss and good heat resistance. It can be suitable for various printing methods, especially for screen printing, plastic packaging boxes and composite films.

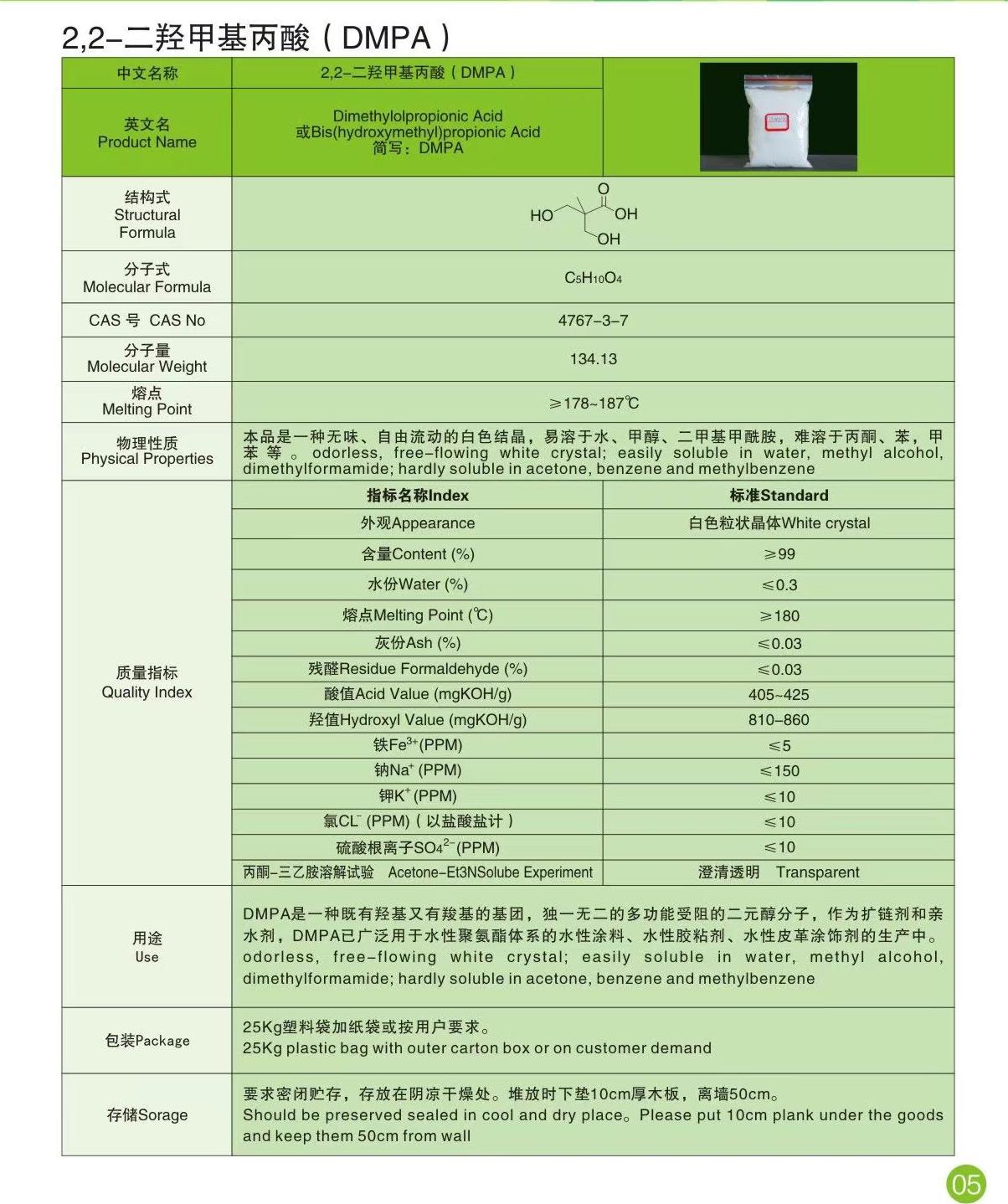

Our company is named Jiangxi Jiyu New Material Co.,ltd. It is specialized in research, manufacturing and selling of Hydrophilic Chain-Extending Agent. For example, 2,2-BIS(Hydroxymethyl) propionic Acid (DMPA) and 2,2-BIS(Hydroxymethyl) butyric acid (DMBA). DMPA and DMBA are widely used in manufacturing of water-based paint, water-based tackiness agent, water-based printing ink and water-based leather finishing agent.